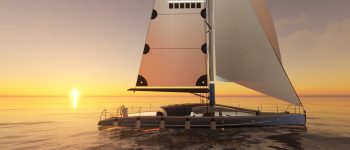

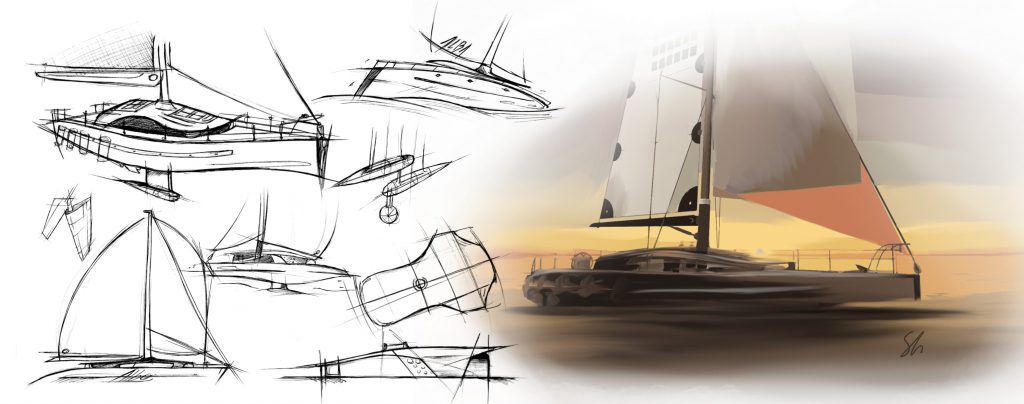

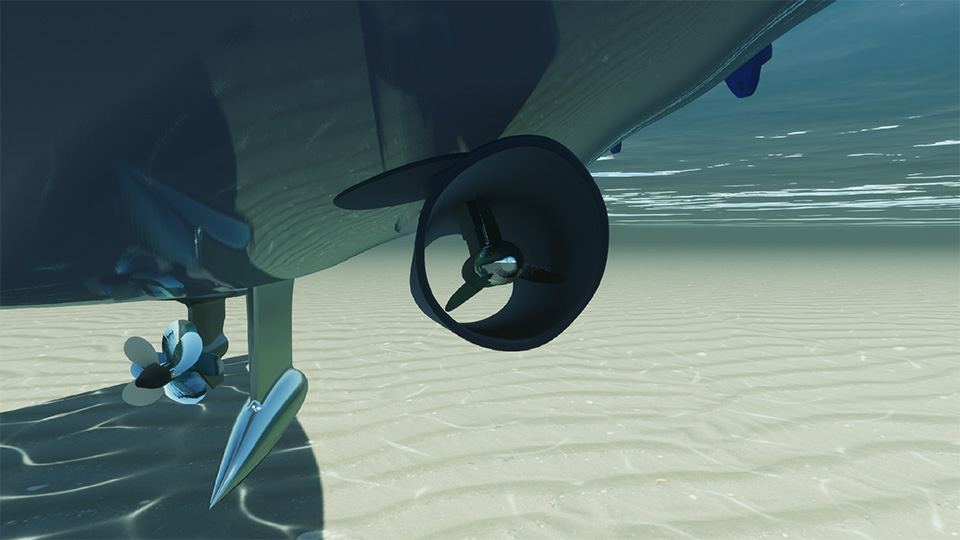

In ALBA, I decided to make the whole boat from scratch starting from the study of existing pleasure sailing boats so boats dedicated to tourist excursions and pleasant and relaxing sailing. I have studied every component of the boat such as the hull, mast and boom and all the elements that a normal sailing boat has, going, however, to add technological components that allow not to use fossil fuels. These components I added consist of two hydrogenerators and 64 solar panels. The hydrogenerators placed on the underside of the boat, under the hull, use the displacement of the boat to produce energy so it results in an environmentally friendly, silent, high-performance solution such that 1 hydrogenerator is able to allow electric autonomy on board. A classic hydrogenerator can charge at 3 knots (5.56 km/h) and generates maximum current at 10 knots (18.52 km/h). And when the boat reaches 10 km/h a hydrogenerator is capable of generating about 3 kW of power which is equal to the consumption inside a house. As for solar panels, I incorporated on the sails and roof of the boat a total of 64 organic solar cells called OPVs. These are an alternative to silicon based on molecular or polymeric absorbers. These cells made by the French company Heole and still under development are encapsulated in different substrates and their strengths are flexibility, light weight, translucency. In addition, among the advantages of these new cells is the load capacity that remains efficient even in average light conditions and whatever the position of the boat with respect to the sun. So the skipper does not have to worry about adjusting the orientation of his sails, plus the sail can be operated for all intents and purposes like a classic nonphotovoltaic sail, thus without a significant impact on performance because of its weight. It can generate 2 to 3 times the daily energy output of silicon panels of the same power output.

As I had previously indicated, the materials used in sailboat construction often have a high level of toxicity and cannot be recycled. Therefore, in the context of the research conducted by ALBA, I chose to adopt innovative and sustainable materials, as well as promote the recycling of many components from boats no longer in use. For example, as a substitute for traditional fiberglass, I opted for a composite made from flax fiber and biodegradable resin developed by Bcomp, a renowned Swiss company. Although the production cost of a ‘flax boat is estimated to be about 10 percent higher than the production of a fiberglass boat, this gap is greatly reduced when the disposal costs of a traditional boat are also considered. I decided to take an environmentally friendly approach to the other parts of the boat as well, including the interior, opting to reuse materials from abandoned boats. This choice aims to drastically reduce our impact on the marine environment and promote the adoption of sustainable practices in the marine industry. This commitment not only demonstrates a commitment to marine conservation, but is also a tangible contribution to a more sustainable future for the boat industry. I devoted time and attention to designing every single area of the boat, from the stern to the bow, including the distribution of interior spaces. In designing the galley and living areas, I aimed to create a welcoming, functional and open space, in stark contrast to many modern boats. This environment was designed to offer the same functionality and comfort as a home, making the dining experience on board enjoyable and uncompromising. My goal was to create an environment where people could move freely, without feeling cramped or confined in space. Regarding the sanitary area, I took an innovative approach. I separated the toilets, such as the toilet and sink, from the shower, thus creating two separate areas. This division not only optimizes space, but also makes using the facilities easier and more convenient. I also designed the bedrooms, leaving ample and flexible space that can be adapted to the needs of the boat owner. This approach to design is not only functional, but also oriented toward the well-being of the occupants, creating a harmonious and functional environment within the boat.

In conclusion, ALBA, a name that reflects hope for a new beginning, is committed to making a significant contribution to building a sustainable future. This project is not only an elegant and light restyling, but also an in-depth investigation into systems and technologies for smarter use of renewable energy. ALBA’s main goal is not only to create an environmentally friendly, state-of-the-art vessel, but also to provide a model that can be adapted and implemented on other vessels, especially larger and more polluting ones. This flexibility and adaptability of the design could be a breakthrough in reducing environmental impact in the shipping industry. I hope that ALBA will not only be an exciting innovation in the present, but also a source of inspiration for future projects, demonstrating that the combination of intelligent design, advanced technology, and sustainability can pave the way for a cleaner and more responsible future.

Local communities: environmental and social impact.

Sector Associations: economic impact.

Investors/Financiers: economic impact.

Developers/Designers: economic and social impact.

Shipbuilders: economic impact.

Technology Providers: economic impact.

Fleet Operators/Owners: economic impact.

Regulators/Government: economic and social impact.

End Users/Customers: environmental and social impact.